Aymo - Pipeline Integrity Management System

Aymo is a state of the art pipeline integrity management software for visualizing, managing and maintaining pipelines, asset integrity and workflows in oil and gas industries.

Service

:Software Development

Client

:Feromihin d.o.o.

Date

:Dec, 2017 – Ongoing

About

Oil and gas industry has a large number of pipelines all over the world which require precise and regular maintenance to avoid and prevent any kind of damage to the pipes linked throughout the pipeline.

Most of the gas or oil transmission system operators have their own systems of managing the data for their pipelines. Every couple of years they will hire a third party company for a specific pipeline inspection.

By doing this, the operators get the inspection data upon which they can detect critical areas and schedule required repairs on the named area.

Challenge

The most detailed inspections are often quite expensive, so they are scheduled every couple of years, ranging from 2 and up to 9 years apart.

With such a wide gap of getting the actual pipeline state information, the operators have to either manually calculate the critical areas where they have the most corrosion growth and degradation of pipeline, or they have to implement their own solution for this calculation.

Even when the new inspection data is obtained, more often than not, the inspections are not aligned due to cut-out changes or rerouting sections on the pipeline. This situation makes the calculations difficult just for the fact that a pipe that was labeled on the 5.000th meter on the first inspection is at the 5.030th meter on the second inspection.

Because there is no pipeline modification tracking, they can not easily match pipes throughout the years, thus getting the wrong results with the corrosion growth calculations and miss the critical areas of the pipeline.

Beside this problem, inspections from different contractors have different report formats and different dataset provided, ranging the most detailed reports to the only reports containing only geolocational points. Taking all of this into account, each operator has to develop their own solution to cover all these cases.

Solution

Aymo is a state of the art pipeline integrity management software for visualizing, managing and maintaining pipelines, asset integrity and workflows in oil and gas industries. It is a cloud based enterprise platform for assessment of pipeline condition, likely threats, risk assessment and mitigation actions to ensure safe and incident free operation of the pipeline system.

We introduced imports as a concept of transfering data into our system with dynamic configuration mapping with which we can import any type of inspection data format.

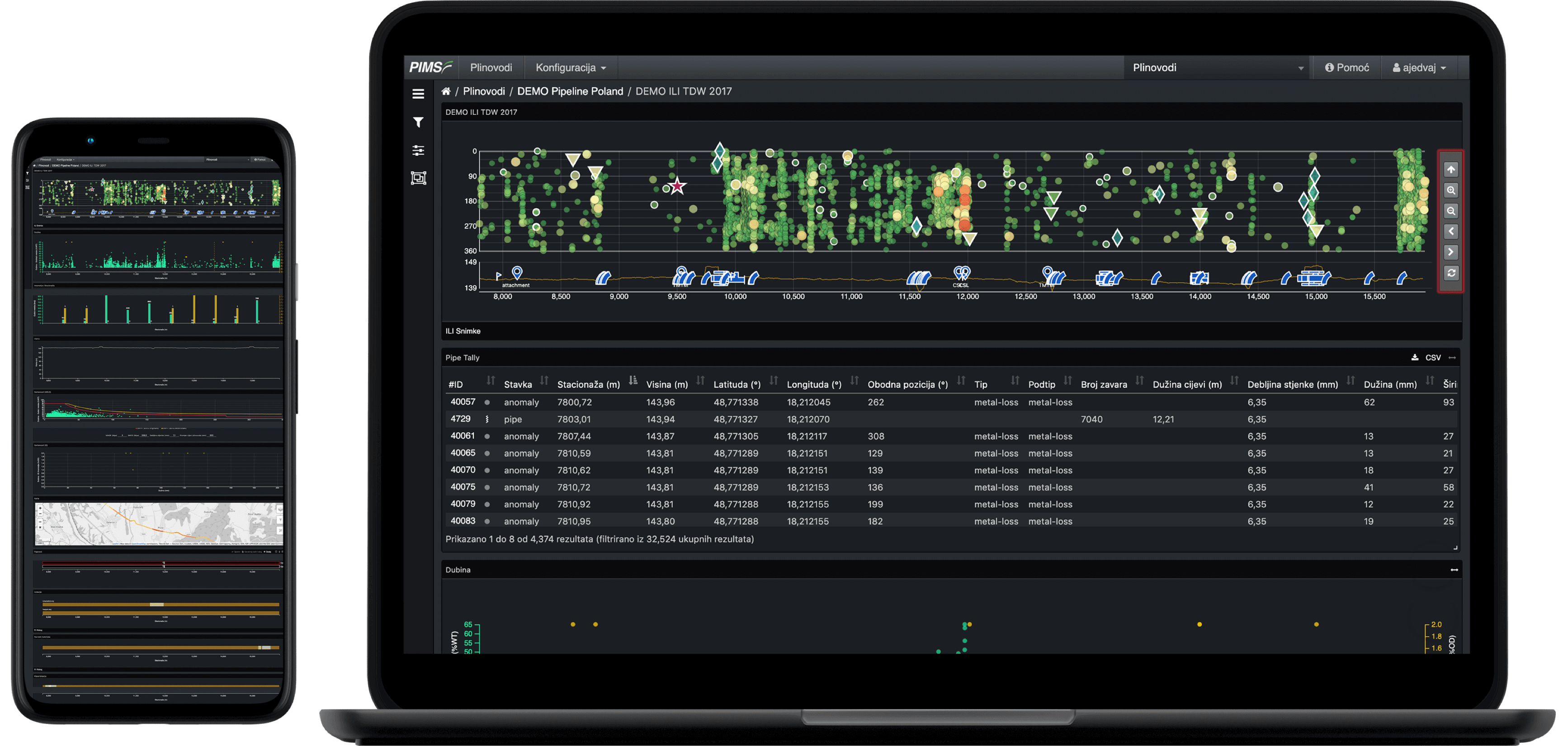

When the data is imported, everything is presented in the data explorer module where the whole pipeline is presented through different types of graphs allowing operators to see the flatten out pipeline with all pipeline entities and visually find critical areas.

Building on top of the virtual model for the pipeline with the addition of pipeline modification builder, operators can now track changes and have a complete overview of the actual state for the physical pipeline.

Following the ability of virtual tracking, an alignment manager was implemented for resolving misaligned inspections over the years, resulting with aligned sections across the pipeline.

On top of the aligned sections, we calculate corrosion growths and detect critical areas for which operators can schedule repair tasks.

- Product design

- Web Design

- Graphic & Print design

- Software and Web Development

- Software Support & Maintenance

- post development integration

- staff education

Results

By using our platform, operators don't have to implement their own solutions or maintain data manually. This lowers the risk of human error and allows for the on-time response for the critical areas of the pipeline.

While tracking the whole pipeline virtually, the operators have an actual state of the pipeline presented to them, with all the modifications that were done on a pipeline. Using our platform, every operator has an ability to combine all different types of inspections on one representation of a pipeline and to extract most of their data through corrosion growth simulations, detections of degradation areas and generally maintaining the best health of their pipelines.

We have successfully implemented Aymo system into state owned gas transport company in Croatia in early 2019 where it is used by operators and engineers to streamline pipeline integrity activities and upgrade their performance.